Solvents elimination/ Desorption of volatile pollutants

Prantner offers highly efficient strippers for the elimination of solvents from water.

- strippers

- compact strippers

- vacuum strippers

Process description

Stripping is a physical process for the removal of undesired contaminants in water. Stripping out of the liquid phase works when the pollutant concentration in the gas phases is lower than the equilibrium concentration in the liquid phase system. The equilibrium is described using so-called Henry Constants. The Henry Constant is dependent on the pollutants in the system, the pressure and the temperature.

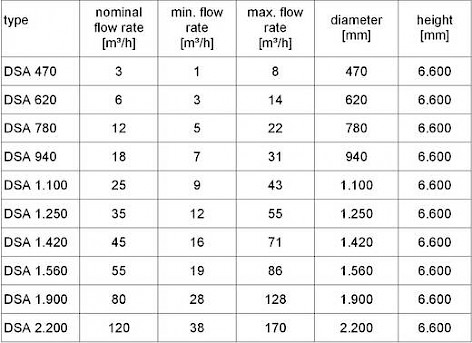

Strippers

This type of stripper is most often used with substances that are easily strippable such as CHC (tetrachloroethene, tricholroethenene) and AHC (benzene, toluene, xylene). They have also been successfully used with less strippable substances such as MTBE and THF at atmospheric pressures - although generally at low concentrations (if no air treatment is required) or when no other more cost effective or efficient processes are available.

Packed Column Stripper

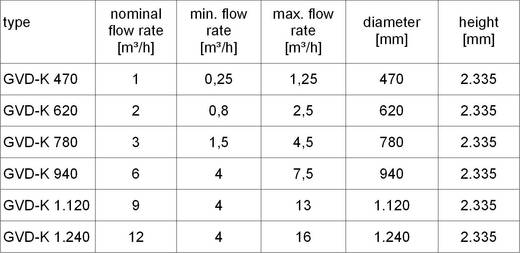

Compact strippers - fit in everywhere

This type of column consists of one or several sieve plates on top of each other. The transfer occurs in the bubble layers directly on the individual plates.

Unquestionable advantages: quickly demountable without screws, no packing materials necessary, compact design, installable anywhere.

These sieve tray systems are also constructed by Prantner to operate in a batched mode and are available under the trading name of "Grenzschichtverdampfer" (Type GVD).

Vacuum strippers generally operate in a pressure range of -0.5 to -0.9 bar. The amount of air coming off the unit to be treated can be greatly reduced.

Pollutants:

Following substances can be efficiently stripped with PRANTNER desorption stripping units:

- Chlorinated hydrocarbons, e.g. Per, Tri, Vinylchloride, Chlorobenzenes etc.

- Aromatic hydrocarbons, e.g. Benzene, Toluene, Xylene, etc.

- Aliphatic hydrocarbons, e.g. Motor fuels

- Polycyclic hydrocarbons, e.g. Naphthalene

- Further solvents such as Tetrahydrofurane etc.

- Ammoniac

- Hydrogen sulphide

Prantner strip / desorption units are manufactured from PE (polyethylene), stainless steel or plastic-coated steel as either single or multi-stage units in a range of standard sizes. The units can be easily adapted to specific applications due to their modular design.

We calculate the exact capacity for you so that your water can be recycled. Prantner strippers are also used for drinking water purification. Request an offer.